news

In addition to thermal insulation and soundproofing,can the

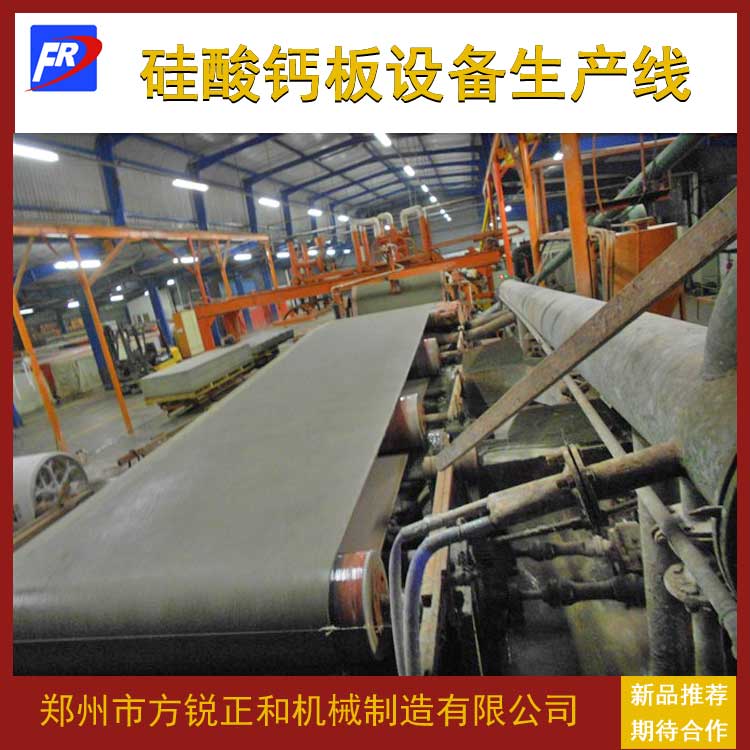

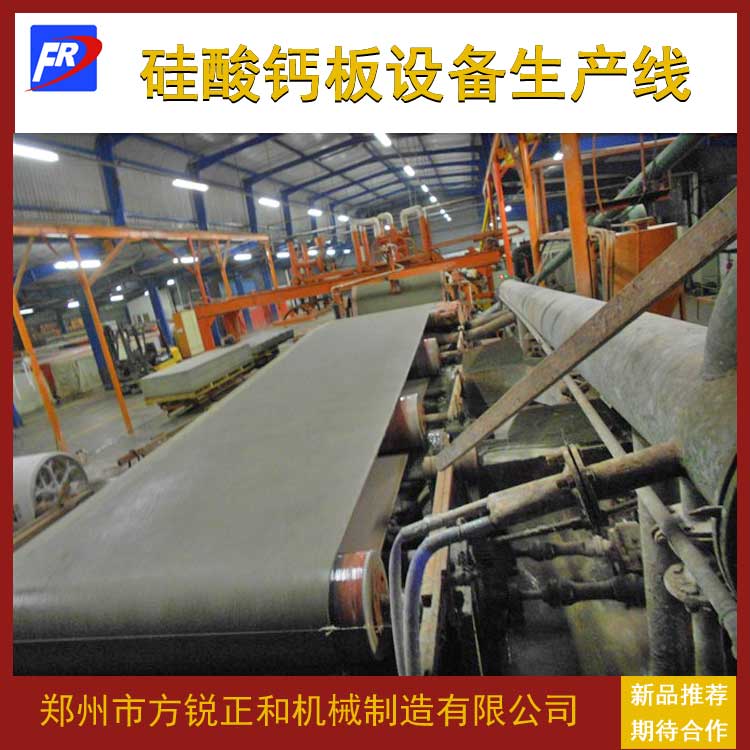

Ordinary calcium silicate boards already have basic fire resistance.The existing calcium silicate board equipment can produce boards with higher fire resistance grades after targeted modification.The modification methods for production lines of different scales are different,as follows:

1.Small and medium-sized production lines:Minor adjustments are sufficient to meet the standards

There is no need to modify the core structure.Only two optimizations are required:First,add an accurate metering device at the feeding end to evenly add fireproof modification materials such as nano-aerogel and reinforcing fibers.Second,fine-tune the autoclave parameters,stabilize the curing temperature at around 185℃and extend the constant temperature time to allow the board to form a dense crystal structure.After the renovation,A1-grade boards with a fire resistance limit of 0.5 to 3 hours can be produced,which are suitable for the fire protection requirements of ordinary buildings.

2.Medium and large-scale production lines:Process upgrading enhances performance

To pursue a 3-4 hour high fire resistance limit,it is necessary to upgrade the supporting facilities:Replace the high-precision slurry box to achieve multi-layer slurry laying and create a composite structure of"fireproof core layer+reinforced surface layer".The upgraded autoclave system adopts the process of"preheating-constant temperature-gradient cooling".If some production lines are modified,the plates will not deform at a high temperature of 800℃and can meet the strict fire protection requirements of industrial scenarios such as metallurgy and chemical engineering.

3.Production Line:Intelligent transformation ensures quality

Introduce online density detection and high-temperature performance monitoring modules to control production parameters in real time.It is equipped with automated cutting and grinding equipment to ensure dimensional accuracy and avoid installation gaps that may affect the fire prevention effect.Some production lines that have introduced imported components can stably produce boards with a fire resistance limit of 4 hours,which are suitable for high-rise buildings,large shopping malls and other scenarios.

The overall renovation cost is controllable.The investment for medium and small-sized lines is low.Although the upgrade cost for medium and large-sized lines is high,the price of high-fire-resistant boards is higher,which can quickly balance the investment.