Information summary:

The sustainable development of calcium silicate tile making machine is an inevitable experience for building materials equipment.The development of the times is getting faster and faster,and the demand is becoming more and more diverse.In o...

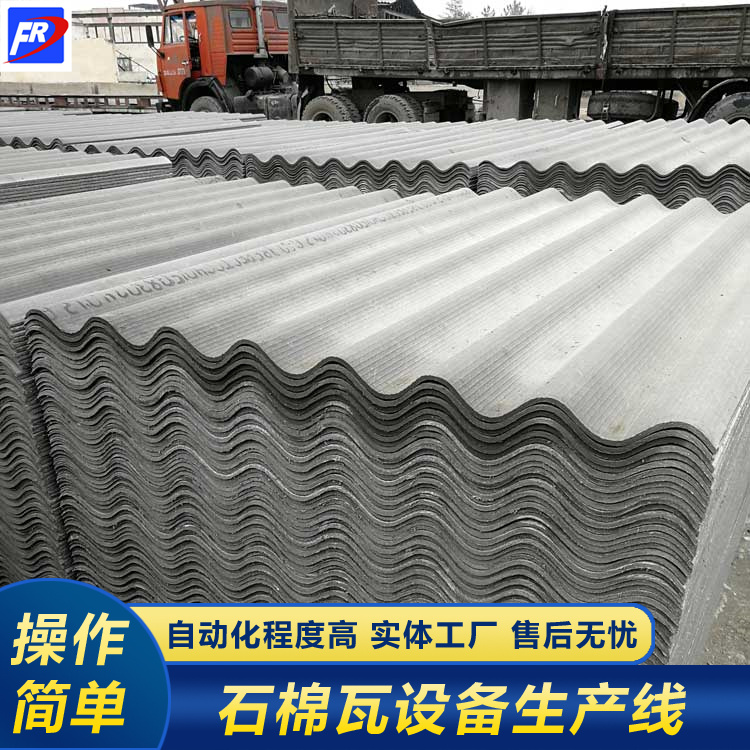

The sustainable development of calcium silicate tile making machine is an inevitable experience for building materials equipment.The development of the times is getting faster and faster,and the demand is becoming more and more diverse.In order to meet the needs of users,the equipment on building materials must naturally be innovative.And update,adjust the structure according to market demand to speed up the pace of application of new technologies,cement fiber tile machine production line to improve efficiency and technical performance.More and more attention is paid to multi-functional,low-consumption devices.

1.The steel structure design of the calcium silicate production line generally adopts the original parts to make the machine more stable and reliable.

2.System design,the use of computer to control the flow pressure of the hydraulic system,improve the product compactness and the use time of the mold box.

3.The equipment adopts PLC and control system,which requires parameter setting,and then makes the machine meet the requirements.

4.Cement fiberboard production line equipment can easily complete large-scale and automatic production.

National Service Hotline

National Service Hotline